The chemicals that feed us, keep us healthy, help us stay clean, and provide the products we use every day need to change.

Chemicals are essential to our modern lives. They are in the shampoos we buy, the medicines we take, and even help to provide us with the food we eat. Plastics, paints, fertilisers, dyes, and the toothpaste you cleaned your teeth with this morning, are all the result of industrial chemical processes. There are few aspects of our daily existence that don’t rely upon the chemical industry to some degree.

While the majority of fossil fuels are used for energy production and transport, around 10% of the coal, oil and natural gas extracted from the ground is turned into raw materials, or feedstocks, for the chemical industry. These provide highly concentrated, readily available forms of carbon that a large part of the organic chemical industry has built itself around for the past century. At the same time, the industry also depends upon the electricity produced using fossil fuels to power its processes. Taken together the chemical industry is responsible for around 6% of global greenhouse gas emissions.

But a change is needed. With governments around the world looking to reduce carbon dioxide emissions in the global effort to tackle human-induced climate change, the chemical industry will need to play its part.

The chemical industry can introduce energy efficiency measures and electrification, for example, to reduce emissions.

Decarbonising the organic chemical industry in its entirety, however, is not a realistic prospect. Carbon is one the few elements that can form long chains of molecules and is able to make fantastic structures that incorporate other elements to produce a wide array of properties. It is the basis of life on this planet – every living thing is packed full of carbon, from the DNA in our cells and the hair on our heads. But it can also form molecules that clean our hair and create containers to hold the shampoo. Carbon is incredibly flexible and fundamental to our modern lives.

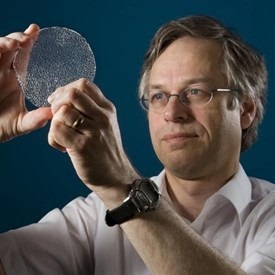

This means looking instead for ways of defossilising the carbon we use to make the products we need. We need “green carbon” to enable the transition away from fossil fuel feedstocks. For the past year I have chaired a working group for The Royal Society on how the chemical industry can find alternative sources of carbon in a net-zero future. We have brought together scientists and engineers from across the disciplines to discuss how to tackle this problem.

And it is not as insurmountable as it might seem.

There are several alternative sources that could provide the carbon we need to support the organic chemical industry. Plants are already proving to be a useful source of carbon that is being turned into polymers to make plastic packaging and bags, for example. Biomass from both crop waste and virgin crops offer a rich supply of carbon that many in both academia and industry are finding ways to utilise. The molecular building block of the common plastic used to make drinks bottles and polyester clothing, Polyethylene terephthalate or PET, has a ring structure that can be replicated using biologically available molecules.

There are also huge amounts of carbon tied up in the polymers we already use and throw away. We live in an age of plastic – 70% of the output from the chemical industry is polymers. But much of that is still thrown away. By repurposing plastics through advanced recycling methods that allow the materials to be broken into their molecular building blocks, we can reform them into new polymers, potentially endlessly.

A third source could be the air itself. Carbon dioxide makes up around 0.04% of the gas in the atmosphere, but its levels have been rising due to human activities. Pulling some of that additional CO2 out of the atmosphere through Direct Air Capture technologies could provide industry with a source of carbon that actually has a positive effect on climate change.

All three are not without their challenges, though. Direct Air Capture of CO2 is still extremely expensive and is not considered feasible anytime soon. In the shorter term, it may be possible to capture carbon from point sources of carbon emissions, such as power stations, cement factories and chemical manufacturing sites – if we overcome challenges such as CO2 purity from some of these sources.

The techniques needed to make sufficient quantities of basic chemicals such as methanol and ethene from sustainable sources of carbon also need to be developed. Around 170 million tonnes of ethene and 100 million tonnes of methanol are produced each year to serve as the primary chemicals in products and processes around the world.

There are also issues around the amount of land that might be needed to produce sufficient biomass and the competing demands between sectors for available biomass. To generate the 12.3 million tonnes of jet fuel currently used by the UK’s aviation industry would require 68% of arable land to be turned over to growing biomass crops. A key challenge is how to meet the needs of the chemical industry without eating into food production further.

Huge amounts of hydrogen will also be needed. It is another key component in organic molecules, and fossil fuels are a plentiful source of it – but this means a lot of emissions. Shifting to other sources of carbon such as biomass, CO2 capture and reusing waste polymers, we will need to generate large amounts of green hydrogen sourced from renewable energy to make the molecules we want.

This is not something that will happen overnight. The transition to sustainable sources of carbon and hydrogen will take time – putting new chemical processes in place and making them productive can take upwards of 15 years. There will also need to be a lot of innovation too. The chemical industry will have to rethink the molecules it uses and make new ones that can do the jobs we currently use fossil-fuel-sourced chemicals for. Some of the science we need already exists, but it needs to be scaled up and made commercially viable. We are also going to need new technologies and to come up with new catalysts, and even create entirely new molecules with the properties we want.

Some research teams, for example, are developing entire new classes of plastic that are easier to repeatedly recycle. We could also look to nature for inspiration – spider webs and the silk made by mulberry worms are just two examples of the extraordinary materials that are produced by nature that we could emulate.

All of this will require intervention, investment and incentivisation from Government to ensure it happens. The public can play their part too by buying products that are sustainably sourced and drive the market in the right direction.

The question is how soon we want to get there.

Read more

The Royal Society has produced a policy briefing exploring the potential to replace fossil feedstocks used in making chemicals with alternative carbon sources.