Links to external sources may no longer work as intended. The content may not represent the latest thinking in this area or the Society’s current position on the topic.

Multi-scale modelling of the structural integrity of composite materials

Theo Murphy scientific meeting organised by Dr Peter Beaumont and Professor Constantinos Soutis.

The nature of cracks that threaten the safety of structures is probed. Material weaknesses that compromise strength are identified. Multi-scale phenomena of the structural changes in composites under stress are modelled. Properly interpreted, structural integrity analysis forecasts the limits of performance of the composite and conditions for safe operation of the engineering structure.

Audio recordings of this meeting are available below. An accompanying journal issue for this meeting was published in Philosophical Transactions of the Royal Society A.

Enquiries: Contact the events team

Organisers

Schedule

Chair

Professor James Marrow, University of Oxford, UK

Professor James Marrow, University of Oxford, UK

Professor James Marrow is the James Martin Chair in Energy Materials. He obtained his undergraduate degree and PhD in Materials Science at Cambridge University, and became a lecturer at Manchester following postdoctoral research at Oxford and Birmingham Universities. Prof. Marrow’s research focuses on degradation of structural materials and the role of microstructure, investigating fundamental mechanisms of damage accumulation using novel materials characterisation techniques. He has pioneered imaging methods for quantification and observation of cracks in engineering materials, and is now leading in the area of three-dimensional studies of damage, using high-resolution X-ray computed tomography and measurement of the three-dimensional full field displacements by digital volume correlation. This is used to validate multi-scale modelling simulations for forward prediction of materials performance in materials such as ceramic matrix composites for accident tolerant nuclear fuel cladding and damage tolerant polymeric matrix composites for aerospace applications.

| 09:05 - 09:30 |

Hierarchical analysis of the degradation of FRP under the presence of void imperfections

The subject of this work is the hierarchical analysis of the degradation of FRP under the presence of void imperfections. To specify the damage accumulation of FRP in the presence of voids, the complex three dimensional structure of the composite inclusive several voids was analysed. Based on this analysis a reduced model composite was derived for mechanical tests. The reduced model composite consists of the matrix and a unique void, which is squeezed between two single fibres, using an injection method. The experimental investigation of the model composite included the description of the stress- and strain behaviour of the matrix using photoelasticity and digital image correlation technology. Additionally, the numerical examination of a parametrical model composite and an analytical study of the stability of a single fibre were conducted. As a result of the experimental investigation of the model composite the failure initiation and propagation could be observed. The failure initiation in the composite is significantly influenced by the stiffness of the matrix and fibres, the fibre foundation and the fibre misalignment. In addition, the aspect ratio of the void leads to stress concentrations in the matrix leading to premature fibre-matrix debonding and to an ongoing loss in stability of the fibre depending on its foundation which finally causes fibre kinking. By increasing the number of fibres and utilised rovings, instead of several fibres respectively, the gained experience made on the examination of the model composite can be transferred to real existing composites. Only by taking the essential boundaries into account the hierarchical analysis can be constructive. This allows an answer to the basic question: “why do composites fail in the presence of voids?”, in particular in terms of the damage initiation and the failure propagation due to void imperfections. In the presentation we span the bow from the experiment (mechanical testing) on void loaded specimens and parts to the numerical interpretation and modelling of its failure behaviour.

Professor Karl Schulte, Hamburg University of Technology, Germany

Professor Karl Schulte, Hamburg University of Technology, GermanyKarl Schulte was head of the Institute of Polymers and Composites of Hamburg University of Technology (TUHH) until September 2013. He studied General Mechanical Engineering at Ruhr-Universität Bochum (Germany). His Ph.D-thesis was on “Fracture Mechanics and Fatigue of Highstrength Aluminium Alloys”. After working with DLR (German Aerospace Research Center) Cologne, Germany he became Professor at TUHH. He had sabbatical leaves at Virginia Tech. in Blacksburg, VA, U.S.A. and University of Cambridge, Department of Materials Science and Metallurgy. His research focused on degradation of fibre reinforced composites, nanocomposites and the synthesis of carbon nanotubes (CNTs) and Aerographite, a 3d graphitic structure. He is European Editor of “Composites Science and Technology”. He published more than 400 peer-reviewed papers. ISIHighlyCited.com listed Prof. Schulte as “Highly Cited Researcher in Material Science”. He is elected By-Fellow of the Churchill College in Cambridge. In 2013 he was named at ICCM-19 as “Composites World Fellow”. In September 2014 he received the “Medal of Excellence in Composite Materials” from the University of Delaware, DA, USA. He continues to work scientifically in the composites field as a consultant and assessor and guides research projects on the synthesis of graphene based nanostructures and polymer nanocomposites. |

|

|---|---|---|

| 09:45 - 10:15 |

The mechanics of reinforcement by nanoplatelets

This presentation will deal with the use of nanoplatelets such as graphene and other 2D materials to reinforce polymers, from both an experimental and theoretical viewpoint. Issues to be covered will include the lateral size of the platelets, number of layers, orientation distribution and surface modification.

Professor Robert Young, University of Manchester, UK

Professor Robert Young, University of Manchester, UKProfessor Young studied Natural Sciences at the University of Cambridge and gained his PhD in 1973. After working at Queen Mary College in London he became Professor of Polymer Science and Technology in Manchester in 1986. From 1992 to 1997 he was the Royal Society Wolfson Research Professor of Material Science. Between 2004 and 2009 he was Head of the School of Materials in the newly-formed University of Manchester. He was elected to the Royal Academy of Engineering in 2006 and to the Royal Society in 2013. Professor Young’s main research interest is the relationships between structure and properties in polymers and composites publishing a number of books and over 350 papers, many of which are highly cited. He has delivered courses in Polymer Science and Technology at both the undergraduate and postgraduate levels and lectured extensively at international conferences. His research interests have extended recently into the field nanotechnology, working in particular upon nanocomposites containing carbon nanotubes or graphene. |

|

| 11:00 - 11:30 |

Failure of notched composites under multi-axial loading

Characterisation and modelling has now got to the degree of maturity that it is possible to compare damage evolution ply-by-ply and inter-ply in composite components under multi-axial loading. As an example, we have explored the notch strength of CFRP laminates, including the mechanisms of damage development. The sensitivity of failure envelope to lay-up and notch geometry is explored, and predictions are made using a combination of delamination and damage models. The accuracy of existing models is evaluated, with a view to vector future modelling activity.

Professor Norman Fleck FRS, University of Cambridge, UK

Professor Norman Fleck FRS, University of Cambridge, UKNorman Fleck has been Professor of Mechanics of Materials at University of Cambridge Engineering Department since 1997. His research is centred on the mechanics of microstructure, ranging from failure of composites to lattice materials. He has pioneered the use of strain gradient plasticity theory to probe size effects in metals. |

|

| 11:45 - 12:15 |

Modelling the development of defects during composite reinforcements and prepreg forming

The deformation modes of composite reinforcement or prepregs with continuous fibers are very specific. The fibers are very stiff in tension but they can slip over one another and their bending stiffness is very small. In order to decrease the number of trial and error tests used in the process developments, simulation codes allow for a more efficient and cost-effective design approach. Wrinkling is one of the most common flaws that occur during textile composite reinforcement forming processes. These wrinkles are frequent because of the possible relative motion of fibres making up the reinforcement, leading to a very weak textile bending stiffness. It is necessary to simulate their onset but also their growth and their shape in order to verify that they don’t extend to the useful part of the preform. The simulation of textile composite reinforcement forming and wrinkling is presented. It is based on a simplified form of virtual internal work defined according to tensions, in-plane shear and bending moments on a unit woven cell. The role of the three rigidities (tensile, in-plane shear and bending) in wrinkling simulations will be analyzed. The onset and development of porosities during the thermoforming of thermoplastic prepregs will also be investigated. The essential role of the reconsolidation stage to remove these defects will be shown. Specific shell elements aiming to model this phenomenon will be presented.

Professor Philippe Boisse, INSA de Lyon, France

Professor Philippe Boisse, INSA de Lyon, FrancePhilippe Boisse is Professor of Mechanical Engineering at INSA Lyon, France. He obtained his PhD in 1987 at University Paris 6 and HDR (accreditation to supervise researches) in 1994. His field of research are Composite forming, Textile composites, Mechanics of fibrous/textile materials, Finite element simulations for forming processes and Thermoforming of thermoplastic composites. He is currently President of the French association for Composites Materials (AMAC). He has been President of ESAFORM (European Association for Material Forming) from 2008 to 2012. He is the director of the GDR (Group of Research) CNRS on composite manufacturing. He is Associated Editor of the International Journal of Material Forming (Springer) and Member of the Editorial Board of Int. J. Composites part B (Elsevier), Int. J. Applied Composite Materials (Springer), Revue des Composites et Matériaux Avancés (Lavoisier). He is director of the “Ecole Doctorale MEGA” Lyon (ED 162). |

Chair

Professor Philippe Boisse, INSA de Lyon, France

Professor Philippe Boisse, INSA de Lyon, France

Philippe Boisse is Professor of Mechanical Engineering at INSA Lyon, France. He obtained his PhD in 1987 at University Paris 6 and HDR (accreditation to supervise researches) in 1994. His field of research are Composite forming, Textile composites, Mechanics of fibrous/textile materials, Finite element simulations for forming processes and Thermoforming of thermoplastic composites.

He is currently President of the French association for Composites Materials (AMAC). He has been President of ESAFORM (European Association for Material Forming) from 2008 to 2012. He is the director of the GDR (Group of Research) CNRS on composite manufacturing. He is Associated Editor of the International Journal of Material Forming (Springer) and Member of the Editorial Board of Int. J. Composites part B (Elsevier), Int. J. Applied Composite Materials (Springer), Revue des Composites et Matériaux Avancés (Lavoisier). He is director of the “Ecole Doctorale MEGA” Lyon (ED 162).

| 13:30 - 14:00 |

Physical modeling of failure in composites under static and fatigue loading

Structural integrity of composite materials is determined by failure mechanisms that initiate at the scale of heterogeneities. The local stress fields and balances between the available and dissipative energy components evolve with the progression of the failure mechanisms. Within the full span from initiation to criticality of the failure mechanisms, the governing length scales in a fiber-reinforced composite structure change from the fiber size to a characteristic fiber-architecture size, and eventually to a structural size, depending on the structural geometry and imposed loading environment. Thus a physical modeling of failure in composites must inherently be of multi-scale nature, although not necessarily with the same hierarchical structure for each failure mode. With this background, the proposed paper will examine the currently available main failure theories of composites to assess their ability to capture the essential features of failure in these material systems. A case will be made for a different approach. An alternative in the form of physical modeling will be presented and its skeleton will be constructed based on systematic observations and considerations of basic failure modes and associated stress fields and energy balances. Both static and time-varying loads will be considered. Some experimental data will be taken to support the proposed approach and methodology.

Professor Ramesh Talreja, Texan A&M University, USA

Professor Ramesh Talreja, Texan A&M University, USADr. Ramesh Talreja is currently Tenneco Endowed Professor in the Department of Aerospace Engineering at Texas A&M University. Prior to that, 1991-2001, he was a professor of aerospace engineering at Georgia Institute of Technology. His early research career was at The Technical University of Denmark, where he received his PhD (1974) and Doctor of Technical Sciences (1985). Dr. Talreja has published extensively in the composite materials field, including a monograph, Fatigue of Composite Materials (1987), Damage Mechanics of Composite Materials (editor, 1994), Polymer Matrix Composites (editor, 2000), and his latest book, Damage and Failure of Composite Materials (with C.V. Singh, Cambridge University Press, 2012). He has written 15 book chapters, given over 200 invited presentations at conferences, universities and industry R&D organizations, taught over 20 short courses, and is or has been on Editorial Boards of 15 international journals. His current interests are in cost-effective and sustainable design of composite structures. |

|

|---|---|---|

| 14:15 - 14:45 |

Environmental degradation of composites for marine structures: new materials and new applications

This presentation will describe the influence of seawater aging on composites used in a range of marine structures, from boats to tidal turbines. The traditional approach to account for aging effects, based on testing samples after immersion for different periods, is evolving towards coupled studies involving strong interactions between water diffusion and mechanical loading. These can provide a more realistic estimation of long term behavior but still require some form of acceleration if useful data, for 20 year lifetimes or more, are to be obtained in a reasonable time (a few months). In order to validate extrapolations from short to long times it is essential to understand the degradation mechanisms, so both physico-chemical and mechanical test data are required. Examples of results from some current studies on more environmentally friendly materials including bio-sourced composites will be described first. These materials offer considerable potential for certain applications but few long term data are available. Then case studies for renewable marine energy applications will be discussed, including an investigation of the durability of carbon fibre reinforced tidal turbine blades. The latter have been studied first on coupons at the material level, then during structural testing and analysis of large components, in order to evaluate long term behavior.

Dr Peter Davies, IFREMER, France

Dr Peter Davies, IFREMER, FranceAfter his PhD on damage in thermoplastic composites and a post-doc at the EPFL Dr Peter Davies has been working at IFREMER, the French Ocean Research Institute, for over 20 years. His interests include mainly composites for marine applications, but also the long term durability of fibres, ropes, adhesives and elastomers. |

|

| 15:30 - 16:00 |

Progressive damage in composites characterised by time lapse x-ray computed tomography

This study investigates the use of time lapse 3D imaging by X-ray micro-computed tomography to follow the evolution of damage as a function of load and time. Either with our without staining it is possible to detect the morphology, number and progress of cracks and damage in 2D laminated and 3D woven composites under a variety of loading scenarios including fatigue testing. Aspects of the technique and examples showing its capability will be presented. Furthermore it will be shown that it is possible to use the 3D models as the geometrical basis for image-based finite element models of damage evolution as well as to establish the validity of conventional representative volume element approaches.

Professor Philip Withers, Regius Professor of Materials, University of Manchester

Professor Philip Withers, Regius Professor of Materials, University of ManchesterProfessor Philip Withers FRS, FREng, FRAeS, FIMMM has made a seminal contribution to our fundamental understanding of the performance of materials through his pioneering use of neutron, synchrotron X-ray and laboratory X-ray beams to provide new insights on behaviour, often in-operando under demanding conditions. He is a Fellow of the Institute of Materials, Minerals and Mining (IoM3, 2004), the Royal Academy of Engineering (2005), the Royal Aeronautical Society (2008) and the Royal Society (2016) and Academia Europaea (2017). He set up the Manchester X-ray Imaging Facility which has one of the most extensive sets of X-ray CT scanners which was awarded the Queen’s Anniversary Medal in 2014. He became the inaugural Regius Professor of Materials in 2017 and is currently Chief Scientist for the Henry Royce Institute for Advanced Materials. Besides being fascinated by understanding how materials behave he is a passionate communicator of science to the public. |

|

| 16:15 - 16:45 |

From matrix nano-phase tougheners to composite macro-properties

High-performance fibre-composites typically employ epoxy resins as the matrix. Epoxies are highly-crosslinked thermosetting polymers, which exhibit good elevated temperature resistance and low creep. However, their high crosslink-density causes them to be relatively brittle polymers. This limits their application as structural materials, as they have a poor resistance to the initiation and growth of cracks. The addition of a second particulate-phase, which is well dispersed, can increase the toughness of thermoset polymers. Thus, an important first goal is to achieve a significant increase in toughness in the 'bulk' epoxy polymer and then to translate this to an improved interlaminar fracture energy, GIc, and impact resistance for the fibre-reinforced composite that employs the toughened epoxy-polymeric matrix. Secondly, with the increased demand for relatively inexpensive resin transfer moulding (RTM) processing - i.e. 'out-of-the-autoclave processing' - the viscosity of the epoxy-resin matrix also needs to be kept to a relatively low value. Thirdly, the toughening second-phase must not be 'strained-out' by the presence of the fibres during RTM processing.

Professor Anthony Kinloch FREng FRS, Imperial College London, UK

Professor Anthony Kinloch FREng FRS, Imperial College London, UKProfessor Tony Kinloch, FREng FRS holds a personal chair as ‘Professor of Adhesion’ in the Department of Mechanical Engineering at Imperial College London. He started his career as a research scientist for the UK Ministry of Defence in 1972. He joined Imperial College London in 1984, and was Department Head from 2007 to 2012. He has published over three hundred and fifty patents and refereed papers and has been awarded the ‘Armourer’s and Braziers Prize for Materials Science’ from The Royal Society, the ‘Le Prix Dédale de la Sociéte Française d’Adhesion’ from the French Adhesion Society, the ‘Hawksley Gold Medal’ of the Institution of Mechanical Engineers, ‘The Griffith Medal’ from the Institute of Materials and the US Adhesion Society 3M Award for ‘Outstanding Excellence in Adhesion Research’. In 1997 he was elected a Fellow of the Royal Academy of Engineering (FREng) and in 2007 was elected a Fellow of The Royal Society (FRS). |

|

| 17:50 - 18:20 |

String and glue - fifty years in composites

This paper presents a very personal, half-century view of the history of advanced composites from the early days before carbon fibers were commercial to today, when they are used in a remarkable range of applications from aircraft to serial production automobiles and countless other products. We concentrate on polymer matrix composites, the dominant class of materials, but consider metal matrix composites, ceramic matrix composites and carbon matrix composites, such as carbon/carbon. While outstanding mechanical properties have been the key driving force for composites, physical properties like thermal conductivity and coefficient of thermal expansion have become increasingly important.

Dr Carl Zweben, Industry Consultant on Composites and Advanced Thermal Materials, USA

Dr Carl Zweben, Industry Consultant on Composites and Advanced Thermal Materials, USADr. Zweben, now an independent consultant on composites and advanced thermal materials, was previously Advanced Technology Manager and Division Fellow at GE Astro Space, later acquired by Lockheed Martin, where he directed the Composites Center of Excellence of the seventeen-department GE Aerospace Group. He was the first, and one of only two winners of both the GE One-in-a-Thousand and Engineer-of-the-Year Awards. Previous positions include Du Pont and the Jet Propulsion Laboratory. |

Chair

Dr Peter Davies, IFREMER, France

Dr Peter Davies, IFREMER, France

After his PhD on damage in thermoplastic composites and a post-doc at the EPFL Dr Peter Davies has been working at IFREMER, the French Ocean Research Institute, for over 20 years. His interests include mainly composites for marine applications, but also the long term durability of fibres, ropes, adhesives and elastomers.

| 09:00 - 09:30 |

Damage in brittle composites: high fidelity simulation of microstructure effects and its experimental validation

Novel analysis methods, such as digital image correlation, provide experimentalists with the tools to detect and quantify damage that can be below the threshold of visible resolution; three dimensional observations within composites may be achieved in suitable microstructures using in situ X-ray computed tomography. These data may inform and also test high-fidelity simulations that model the development of damage in composites. The challenge lies in appropriate treatment of the high-resolution characterisation of large representative volumes of microstructure, which can easily lead to inoperable models unless homogenisation is done to reduce the model's computational cost. Homogenisation, however, results in a loss of detail.

Professor James Marrow, University of Oxford, UK

Professor James Marrow, University of Oxford, UKProfessor James Marrow is the James Martin Chair in Energy Materials. He obtained his undergraduate degree and PhD in Materials Science at Cambridge University, and became a lecturer at Manchester following postdoctoral research at Oxford and Birmingham Universities. Prof. Marrow’s research focuses on degradation of structural materials and the role of microstructure, investigating fundamental mechanisms of damage accumulation using novel materials characterisation techniques. He has pioneered imaging methods for quantification and observation of cracks in engineering materials, and is now leading in the area of three-dimensional studies of damage, using high-resolution X-ray computed tomography and measurement of the three-dimensional full field displacements by digital volume correlation. This is used to validate multi-scale modelling simulations for forward prediction of materials performance in materials such as ceramic matrix composites for accident tolerant nuclear fuel cladding and damage tolerant polymeric matrix composites for aerospace applications. |

|

|---|---|---|

| 09:45 - 10:15 |

A-FEM for high fidelity multi-scale failure analysis of structural composites

Advanced composites have been increasingly used as primary load-bearing structures or structural members. While they offer many excellent properties, significant concerns regarding their long term durability and safety remain. One particular unsolved challenge is to quantify the uncertainty associated with the service life. Typical composites exhibit complex, multiple damage events including multiple crack initiation events within and between plies/tows from pristine materials, through their coupled growth, involving multiple bifurcation, coalescence, and ply-jumping, to eventual failure. Numerical and/or analytical methods capable of predicting the progressive damage evolution in composites under general thermal-mechanical loadings and quantifying their effects on structural integrity are in high demand. High-fidelity thermal-mechanical analyses to composite structures with explicit consideration of arbitrary crack-like damage events are challenging because the heterogeneous nature of composites makes it impossible to know the cracking locations a priori, yet efficient accounting of the nucleation, coalescence, and bifurcation of multiple damage processes is critical to simulation fidelity. There are several methods that can deal with arbitrary cracking in solids such as the extended FEM (X-FEM) and the phantom-node-method (PNM). These methods typically employ crack tip enrichment functions through portioning-of-unity, which are inherently nonlocal and are difficult in handling merging or bifurcating cracks. The need for extra DoFs or nodes for new or propagating cracks also makes these methods inflexible in treating crack interaction. In this study, we present a multiscale simulation platform based on our newly developed augmented finite element method (A-FEM). We shall demonstrate that the A-FEM is able to achieve high fidelity simulations of multiple, arbitrary damage evolution processes in composite structures with an improved numerical efficiency of several orders of magnitude. The capability of the new A-FEM will be demonstrated through several case studies on realistic composite systems at various important scales. Important information regarding how the microscopic damage processes and their evolution can impact the macroscopic structural performance/integrity will be discussed.

Professor Qingda Yang, University of Miami, USA

Professor Qingda Yang, University of Miami, USADr. Qingda Yang is an associate professor at the University of Miami (Coral Gables, FL). He obtained his B.S. (1991) and M. S. (1994) from Zhejiang University, China, and a PhD (2000) from University of Michigan at Ann Arbor. Prior to joining University of Miami, Dr. Yang worked for Rockwell Science Center as a solid mechanics scientist from 2000 to 2006. Dr. Yang’s recent research has been focused mainly on developing multi-scale methodologies for virtual testing and designing of complex heterogeneous materials and structures. Dr. Yang is an author/coauthor of 70 peer-reviewed journal publications, 4 book chapters, and more than 30 refereed conference proceedings. He is an editorial board member for the Journal of Applied Composite Materials and the journal of Multifunctional Composites, and an executive board member for the Florida Space Grant Consortium (FSGC). He has been selected as the UM Fellow of Faculty Learning Community since 2012. |

|

| 11:00 - 11:30 |

Multi-scale characterization and representation of composite materials during processing

The worlds of structural simulation and process simulation are rapidly converging as it becomes increasingly clear that failure predictions can be significantly enhanced if process-induced conditions and defects are captured in the structural simulation. Processing outcomes that affect structural response range from thermal outcomes (e.g. degree of cure or crystallinity, physical morphology), to quality outcomes (e.g. ply thickness, volume fraction, wrinkling and waviness, porosity), or mechanical outcomes (e.g. dimensional change and residual stress). The state of the art in modelling these outcomes as a function of processing conditions is quite varied in terms of rigour, completeness, breadth, integration, and application. Broadly speaking, there are three ranges of matrix response where different simulations strategies can be applied: (a) high temperature, low cure/crystallinity where the system is essentially fluid like and viscous; (b) mid-temperature, gelled or crystallized where the system is viscoelastic; and (c) lower temperature, below the glass transition temperature, where the system is essentially elastic. The behaviour of the system must also be considered at all scales, which in processing includes not only the classical micro-scale, meso-scale, layer/lamina scale, and structural scale, but also the tooling, equipment and other associated manufacturing initial and boundary conditions. Here we present some of our most recent work in creating a coherent and consistent framework for process modelling, and provide experimental and simulation results to highlight both successes and needs. In particular, we focus on residual stress development under different thermal histories, and show how a multi-scale modelling approach can be exercised to evaluate and predict different aspects of this problem.

Professor Anoush Poursartip, University of British Columbia, Canada

Professor Anoush Poursartip, University of British Columbia, CanadaPoursartip directs the Composites Research Network at UBC, which aims to bridge the gap between academic research and industrial practice for composites manufacturing. Poursartip is also a co-founder of Convergent, a world leader in process design software, instrumentation and support for the international aerospace industry. Poursartip has been on the Executive Council of the International Committee on Composite Materials since 1995, as well as serving as General Secretary and President. Poursartip is a World Fellow of ICCM, Fellow of the Canadian Academy of Engineering, and Fellow of SAMPE. He has won multiple awards from The Boeing Company, the Medal of Excellence from the Center for Composite Materials (CCM) at the University of Delaware, and the Wayne Stinchcomb award from ASTM. |

|

| 11:45 - 12:15 |

Computational micromechanics of composites: a mature discipline?

Computational micromechanics is emerging as an accurate tool to study the mechanical behaviour of composites at the micro scale due to the sophistication of the modeling tools and to the ever-increasing power of digital computers [1]. Within this framework, the macroscopic properties of a composite or heterogeneous material can be obtained by means of the numerical simulation of the deformation and failure of a statistically representative volume element of the microstructure. As compared with classic homogenization techniques, computational micromechanics presents two important advantages. Firstly, the influence of the geometry and spatial distribution of the phases (i.e. size, shape, clustering, connectivity, etc.) can be accurately taken into account. Secondly, the details of the stress and strain microfields throughout the microstructure are resolved, leading to precise predictions of the onset and propagation of damage. Recent advances in this area include the analysis of the effect of different fiber (carbon and glass [2]), interfaces [3], spatial distribution and ply thickness or the influence of damage on the final mechanical performance of fiber-reinforced composites [4,5], as well as the physical determination by detailed experimental techniques based on instrumented nanoindentation [6,7] of the parameters governing the mechanical behavior of the composite at this length scale. [1] Llorca, J; Gonzalez, C; Molina-Aldareguía, J M; Segurado, J; Seltzer, R; Sket, F; Rodriguez, M; Sadaba, S; Munoz, R; Canal, L P, Multiscale modeling of composite materials: a roadmap towards virtual testing, Advanced materials, 23, 5130-47, 2011, DOI: 10.1002/adma.201101683. [2] E. Totry, J. M. Molina-Aldareguia, C. González, J. Llorca. Effect of fiber, matrix and interface properties on the inplane shear deformation of carbon-fiber reinforced composites. Composites Science and Technology, 70, 970-980, 2010. [3] C. González and J. Llorca. Mechanical behaviour of unidirectional fiber-reinforced polymers under transverse compression: Microscopic mechanisms and modelling. Composites Science and Technology, 67, 2795-2806, 2007. [4] LP. Canal, C. González, J. Segurado, J. LLorca, Intraply fracture of fiber-reinforced composites: Microscopic mechanisms and modeling, Composites Science and Technology, 72, 1223-1232, DOI:10.1016/j.compscitech.2012.04.008, 2012. [5] C. González and J. Llorca. Multiscale modelling of fracture in fiber-reinforced composites. Acta Materialia, 54, 4171-4181, 2006. [6] M. Rodriguez, JM. Molina Aldareguia, C. González, J. LLorca, A methodology to measure the interface shear strength by means of the fiber push-in test, Composite Science and Technology, 72, 1924-1932, DOI:10.1016/j.compscitech.2012.08.011, 2012. [7] M. Rodriguez, JM. Molina-Aldareguia, C. González, J. LLorca, Determination of the mechanical properties of amorphous materials through instrumented nanoindentation, Acta Materialia, 60, 3953-3964, DOI: 10.1016/j.actamat.2012.03.027, 2012.

Professor Carlos González, Polytechnic University of Madrid and IMDEA Materials Institute, Spain

Professor Carlos González, Polytechnic University of Madrid and IMDEA Materials Institute, SpainProf. Carlos González (PhD Polytechnic University of Madrid, 2000) is the head of the Composite Materials group at IMDEA Materials Institute and Associate Professor of Materials Science at the Polytechnic University of Madrid. His research activities have been focused in one of the main areas of the Materials Science and Engineering: analysis of the relationship between the microstructure of the materials and their physical properties, particularly of the mechanical properties of advanced structural materials, mainly composites. Theses research activities have been carried out within the framework of more than 20 research projects funded by regional, national and international R&D programs and through contracts with companies (Airbus, EADS-CASA Espacio, Acciona, Gamesa, Anci, Future Fibers, etc). Dr. González is author of more than 60 scientific papers in international peer-reviewed journals, which have received over 1000 cites (h index of 19). Some of those papers are considered as highly cited papers according to the thematic net ISI Web of Knowledge in the field of solid mechanics and even appear referenced in prestigious journals such as Science on the future prospects of the virtual simulation techniques. |

Chair

Professor Karl Schulte, Hamburg University of Technology, Germany

Professor Karl Schulte, Hamburg University of Technology, Germany

Karl Schulte was head of the Institute of Polymers and Composites of Hamburg University of Technology (TUHH) until September 2013. He studied General Mechanical Engineering at Ruhr-Universität Bochum (Germany). His Ph.D-thesis was on “Fracture Mechanics and Fatigue of Highstrength Aluminium Alloys”. After working with DLR (German Aerospace Research Center) Cologne, Germany he became Professor at TUHH. He had sabbatical leaves at Virginia Tech. in Blacksburg, VA, U.S.A. and University of Cambridge, Department of Materials Science and Metallurgy. His research focused on degradation of fibre reinforced composites, nanocomposites and the synthesis of carbon nanotubes (CNTs) and Aerographite, a 3d graphitic structure.

He is European Editor of “Composites Science and Technology”. He published more than 400 peer-reviewed papers. ISIHighlyCited.com listed Prof. Schulte as “Highly Cited Researcher in Material Science”. He is elected By-Fellow of the Churchill College in Cambridge. In 2013 he was named at ICCM-19 as “Composites World Fellow”. In September 2014 he received the “Medal of Excellence in Composite Materials” from the University of Delaware, DA, USA. He continues to work scientifically in the composites field as a consultant and assessor and guides research projects on the synthesis of graphene based nanostructures and polymer nanocomposites.

| 13:30 - 14:00 |

Progress in the pursuit of reliable bonded composites

Reliable and durable adhesive bonding is an indispensable capability that would permit the structural designer to utilize the many inherent capabilities of composites. Until very recently, reliable adhesive bonding depended upon rigid compliance with quality control procedures, which too often did not produce long-term reliable bonds.

Dr Robert Crane, US Air Force Research Lab, USA

Dr Robert Crane, US Air Force Research Lab, USARobert Crane graduated from Ohio State University in 1965 with a Bachelor of Engineering degree and in 1969 with a doctorate in materials science and engineering. He subsequently worked for the U. S. Air Force Materials Laboratory for 38 years in a variety of positions. Much of his research work involved developing new methods of inspecting composite materials and adhesive bonds. During that time, he pioneered the use of computer tomography for the inspection of composite structures, a method to measure the strength of an adhesive bond in situ and other inspection capabilities associated with composite materials and structures. He also worked in optics on a number of projects including optical polymers, nonlinear optical materials, and biopolymers. He was honored by the Air Force Research Laboratory by his election to the position of Fellow in 2001. He has served on numerous committees such as the Columbia Accident Investigation Board. |

|

|---|---|---|

| 14:15 - 14:45 |

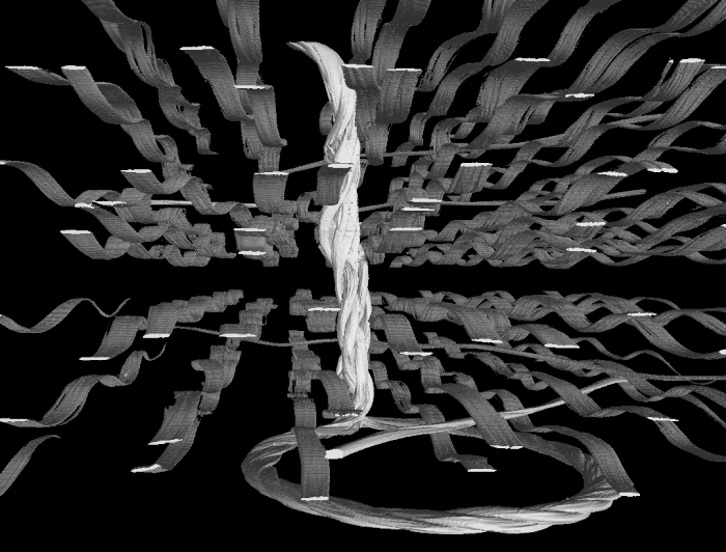

Use of microfasteners to produce damage tolerant composite structures

The traditional low delamination resistance of classical laminated composites can be tackled successfully by the insertion of rigid microfasteners along the through-thickness direction, at least as far as resistance to crack growth is concerned. This much has been established for some time now, initially for nails in wood, more recently for the case of thin rigid composite rods (‘Z-pins’) inserted into a prepreg stack prior to cure and for thin threads stitched or tufted into dry fibre preforms prior to resin infusion and cure. Metal to composite bonding can be improved in a similar fashion through the use of metallic pins on the metal adherend. Recent work shows how multi-material microfasteners can be exploited to deliver a mechanical advantage coupled with advantageous changes to thermal and electrical attributes such as self-sensing. Through-the-thickness reinforcement has been demonstrated to deliver significant increases in delamination resistance under Mode I dominated loading modes in quasi-static as well as impact and fatigue conditions. The balance of out-of-plane and in-plane properties of thus reinforced composite is dependent on the parameters of the reinforcement but also on the stacking sequence and the thickness of the composite. Parametric studies are therefore best carried out via multi-scale modelling, based on experimental determination of the crack bridging laws from a single microfastener placed in the relevant structural environment. In practice, the insertion of the microfasteners can be controlled well, but subsequent movements and deformation in the debulking and cure stages of the processing are much more difficult to manage. Modelling can predict the effects of microfastener mis-alignment on mechanical or functional performance and the influences are shown to be considerable. Further progress therefore needs to be made in the control of the processing steps and in QA of such complex structures.

Professor Ivana Partridge, University of Bristol, UK

Professor Ivana Partridge, University of Bristol, UKProfessor Ivana Partridge BA MA PhD FIMMM read Natural Sciences (Experimental Physics) at Newnham College, Cambridge. She joined Cranfield University in 1979, gaining her PhD there on the topic of toughened thermosetting resins. She remained on the academic staff at Cranfield for 33 years, leaving the post as Head of Composites Centre in 2012. Since transferring to the ACCIS group at the University of Bristol she has directed its new EPSRC Industrial Doctorate Training Centre in Composites manufacture and continues in an active research role, joining the University outputs with the more applied research at the National Composites Centre in Bristol. She is current vice-chair of the British Composites Society, IoM3. |

|

| 15:30 - 16:00 |

Limits of sustainable damage in filament wound structures under short and long-term loading revealed by Multi-scale modelling

Internally pressurised filament wound carbon fibre reinforced composite structures accumulate damage in the form of fibre breaks throughout their use. This raises the possibility of unexpected rupture with possible catastrophic consequences. It has been shown that the viscoelastic nature of the matrix material accounts for the progressive damage of the material. Multi-scale modelling from the level of individual fibres to that of the whole structure is now feasible due to increases in computational power. It will be shown that such an approach models accurately the rate of damage observed both in simple unidirectional composites and filament wound composites and allows damage to be described quantitatively both as a function of applied stress and also time. The ability to determine rates of damage and also critical damage levels, under a variety of loading conditions, which would lead to rupture, allows intrinsic safety factors to be calculated for structures such as pressure vessels used to store gases, including hydrogen and methane, at very high pressures for which failure cannot be envisaged. It will be shown how multi-scale modelling allows a more detailed understanding of the kinetics of damage accumulation both under monotonic loading but also sustained long-term loading similar to that which would be experience in such structures during their in-service lives. It is expected that this approach should contribute to the redefining of international standards for testing and assessing filament wound composite pressure vessels and also allow them to be designed to be both economical and reliable.

Professor Tony Bunsell, Mines Paris Tech, France

Professor Tony Bunsell, Mines Paris Tech, FranceAnthony Bunsell has worked on advanced composites since the early 1970s with primary research interests into the relationship between microstructure and mechanical properties of both their fibre reinforcements and composite structures. This has included studies into the effects of the environment on the behaviour of composites. For more than forty years a primary interest has been into the long term reliability of carbon fibre composite pressure vessels. With help from collaborators he has been interested in quantifying damage in these structures when they are subjected to loadings lasting from minutes to decades with the aim of ensuring their reliability when in service. This has led to the development of models which describe accurately the development of damage processes at the level of the fibres and allow the intrinsic safety factors of such composite structures to be quantified. |

|

| 16:15 - 17:00 |

Panel Discussion

Dr Alastair Johnson, Consultant DLR iR, Germany

Dr Alastair Johnson, Consultant DLR iR, GermanyDr Alastair Johnson studied Mathematics followed by research on polymer composites at the National Physical Laboratory, Teddington, UK, later becoming Head of the NPL Composites Properties and Design Group. In 1990 he moved to the German Aerospace Center (DLR), Institute of Structures and Design, Stuttgart, with responsibility for design of composite materials and aerospace structures within the Structural Integrity Department. Since his retirement in 2010 he is a consultant in the field of damage tolerance and safety of composite aircraft structures. Research interests include the FE modelling of composites damage and failure properties, composite materials and structural testing, properties and design of sandwich structures, damage tolerance of composite aircraft structures under impact and crash loads. Extensive experience on structural integrity of composite aircraft structures was obtained through working with international industry and research partners, including coordination of two large EU Aeronautics research projects. He is an Associate Editor of the journal Applied Composite Materials, international member of the EPSRC Peer Review College, and member of the FAA CMH-17 Crashworthiness Working Group.

Dr Tony Waas, University of Michigan, USA

Dr Tony Waas, University of Michigan, USA

Dr Carl Zweben, Industry Consultant on Composites and Advanced Thermal Materials, USA

Dr Carl Zweben, Industry Consultant on Composites and Advanced Thermal Materials, USADr. Zweben, now an independent consultant on composites and advanced thermal materials, was previously Advanced Technology Manager and Division Fellow at GE Astro Space, later acquired by Lockheed Martin, where he directed the Composites Center of Excellence of the seventeen-department GE Aerospace Group. He was the first, and one of only two winners of both the GE One-in-a-Thousand and Engineer-of-the-Year Awards. Previous positions include Du Pont and the Jet Propulsion Laboratory.

Professor Constantinos Soutis, University of Manchester, UK

Professor Constantinos Soutis, University of Manchester, UKProfessor Constantinos Soutis PhD(Cantab), FREng holds the Chair in Aerospace Engineering, he is the Director of the Aerospace Research Institute and Director of the Northwest Composites Centre at the University of Manchester. He has over 25 years of experience in working with composite structures. On 5 August 2014 he was elected as a Fellow of the Royal Academy of Engineering. Professor Soutis is distinguished for his major contributions to the science and technology of the mechanics and mechanisms of failure of fibre-composite materials based upon polymeric matrices. His research is innovative and world-leading. The output from his research is being used extensively by major companies working with composite materials. The Academy's Fellows represent the nation’s best engineering researchers, innovators, entrepreneurs, business and industry leaders. His industrial experience includes work with the Structural Materials Centre of the Defence Evaluation & Research Agency (visiting research fellow, 1995-2001), QinetiQ (Trusted Expert, 2001-2003), Cambridge Consultants, Cytec Materials Engineering and ABB Research in Switzerland. He is the author or co-author of over 350 archived articles, and some 25 PhD students have qualified under his guidance. Professor Soutis is a Deputy Editor of the Journal of Applied Composite Materials and Associate Editor of the RAeS Aeronautical Journal.

Professor Samit Roy, University of Alabama, USA

Professor Samit Roy, University of Alabama, USA |