Links to external sources may no longer work as intended. The content may not represent the latest thinking in this area or the Society’s current position on the topic.

New horizons for nanocellulose technology

Scientific discussion meeting organised by Professor Alan Windle FRS, Professor Steve Eichhorn, Dr Silvia Vignolini and Dr Sameer S. Rahatekar.

This discussion meeting will focus on the fundamental chemical, physical properties of cellulosic materials in nature and their future utilisation for engineering materials and bioeconomy. The programme of distinguished speakers, whose backgrounds reflect the interdisciplinary nature of research into cellulosic materials, will provide a dynamic, border-crossing and thought-provoking review of this emerging area.

The schedule of talks and organiser/speaker biographies are available below. Speaker abstracts will be available closer to the meeting date.

Recorded audio of the presentations will be available on this page after the meeting has taken place. Meeting papers will be published in a future issue of Philosophical Transactions A.

Poster session

There will be a poster session at 17:00 on Tuesday 2 May 2017. If you would like to apply to present a poster please submit your proposed title, abstract (not more than 200 words and in the third person), author list, name of proposed presenter and institution, to the Scientific Programmes team no later than Monday 27 March 2017. Please include the text 'Poster abstract submission: Nanocellulose' in the email subject line. Please note that places are limited and posters are selected at the scientific organiser's discretion. Poster abstracts will only be considered if the presenter is registered to attend the meeting.

Enquiries: Contact the Scientific Programmes team

Organisers

Schedule

Chair

Professor Alan Windle FRS, Department of Materials Science & Metallurgy, University of Cambridge, UK

Professor Alan Windle FRS, Department of Materials Science & Metallurgy, University of Cambridge, UK

Alan Windle’s central contribution to polymer science has been in the study of the degrees of structural order intermediate between fully crystalline and amorphous (liquid-like). The hallmark of his work has been innovative diffraction analysis closely coupled with the development of computer methods of molecular modelling. This approach confirmed the replacement of the meander model of the glassy state by the random coil theory, and also provided the first conformational models of a series of glassy polymers. He developed new ways of measuring and understanding molecular orientation in deformed polymers, and his studies of polymer–solvent systems led to a theory of ‘case II’ diffusion, which is now widely accepted and exploited. His research on liquid crystalline polymers has been rewarded by a detailed understanding of the development of microstructure, and in particular by new insights into the crystallisation of random copolymers which depend on the matching of aperiodic sequences.

| 09:00 - 09:05 | Welcome by the Royal Society | |

|---|---|---|

| 09:05 - 09:45 |

Development of Advanced Lignocellulosic Bioproducts from Multiphase Systems

Professor Orlando Rojas, Department of Bioproducts and Biosystems, Aalto University, Finland

Professor Orlando Rojas, Department of Bioproducts and Biosystems, Aalto University, FinlandDr Rojas is Professor of Bio-based Materials in Aalto University (Finland). He holds adjunct appointments with the departments of Chemical and Biomolecular Engineering and Forest Biomaterials of North Carolina State University. Earlier in his career, he was a senior scientist appointed by the Royal Swedish Academy of Sciences in the Royal Institute of Technology (KTH), a postdoctoral fellow in the Institute for Surface Chemistry, Sweden and research assistant in Auburn University. He was selected as Finland Distinguish Professor (2009-2014) and was Chair of the “Division of Cellulose and Renewable Materials” of the American Chemical Society (2009-2011). He was awarded with the distinction of Fellow of the American Chemical Society (2013) for his scientific and professional contributions. He is the recipient of the 2015 Nanotechnology Division Technical Award and IMERYS Prize for outstanding contributions that have advanced the industry's technology. He was appointed as a “2013-2017 Faculty Scholar” (Inaugural edition) of NCSU and ACS Division Award of “Cellulose and Renewable Materials”. His work is centered on the utilization of lignocellulosic materials in novel, high performance applications and the interfacial and the adsorption behaviors of surfactants and biopolymers at solid/liquid interfaces. He has published over 230 peer-reviewed papers related to these topics. He and his students have given +300 conference presentations and has been invited numerous times (+200) as a speaker in conferences, universities and research centers worldwide. The recent efforts of his group, “Bio-based Colloids and Materials”, deal with the development of nanostructures from the fiber cell wall and cellulose derivatives, the dynamics of enzymatic reactions and the design of stimuli-responsive materials and multiphase systems. |

|

| 09:45 - 10:30 |

Hybrid Superlattice Structures From Nanocellulose and Inorganic Materials

Hybrid materials containing nanoscaled cellulosic constituents can be an attractive choice for example for thermoelectric energy harvesting, since it is possible to fabricate layered superlattice structures and inorganic multilayer structures by incorporating various grades of nanocellulosic materials. The aim of the presentation is to introduce approaches to construct both type of the structures (superlattice and inorganic multilayer structures) using various nanoscaled cellulosic materials such as cellulose nanocrystals (CNC), cellulose nanofibrils (CNF) and TEMPO-oxidized CNF with Earth-abundant inorganic components. Ultrathin cellulose layers have been prepared using spin coating or dip coating whereas inorganic layers have been constructed using atomic layer deposition (ALD) method. Superlattice structures with alternating layers of various nanocellulosic materials and ZnO showed that resistivity and thermal conductivity of such structures can be manipulated by the cellulosic thin layer nanoarchitecture. Inorganic multilayer structures consisting of stacks of SiO2/Al2O3 with individual layer thickness values of 3.7 nm and 2.6 nm for SiO2 and Al2O3, respectively. Such multilayer structure fabricated on self-standing films of cellulose nanofibrils (CNF) efficiently blocked the diffusion of the oxygen molecules through the CNF film structure. Moreover, simultaneously developed low temperature ALD processes for ZnO, SiO2 and Al2O3 enabled the coating of thermally sensitive biomaterials by inorganic thin films.

Dr Docent Tekla Tammelin, VTT Technical Research Centre, Finland

Dr Docent Tekla Tammelin, VTT Technical Research Centre, FinlandMs Tekla Tammelin (D.Sc. (Tech.), Principal Scientist in Fibres and Biobased Materials Research area and Docent in Bioproduct Technology at Aalto University. Her research is focused on biomaterials’ surface behaviour, formation of structures and interfacial phenomena including adsorption and self-assembly. She is currently acting as a member in a senior expert network in VTT SONE (Solutions for Natural Resources and Environment) Business Area with an internal role as Principal Investigator with the strategic research responsibility area of “Nanocellulosic materials”. She is a main inventor of the recent patent related to the larger scale preparation method for nanocellulosic films. She has ~50 peer-reviewed papers and over 80 scientific meeting proceedings and she received Akzo Nobel Nordic Research Prize in 2010 in the area of surface chemistry of cellulosic fibres. |

|

| 10:30 - 11:00 | Coffee break | |

| 11:00 - 11:45 |

Order and Gelation of Cellulose Nanocrystal Suspensions

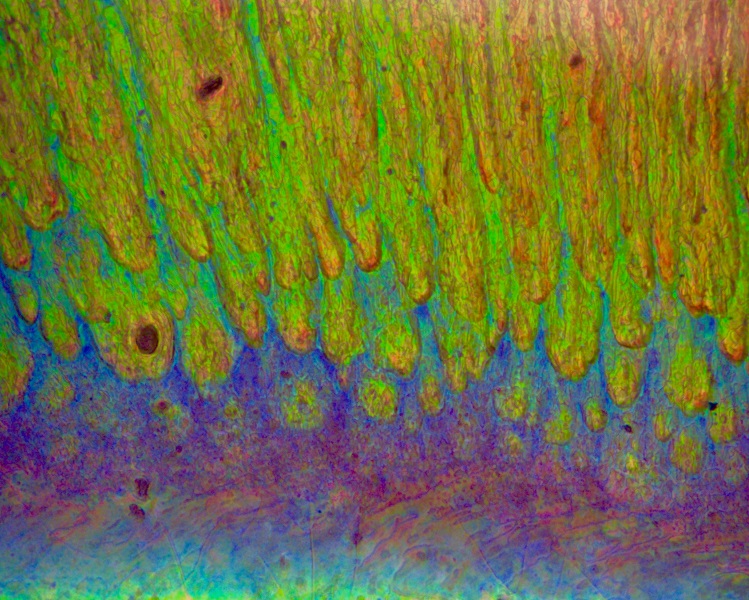

Cellulose nanocrystals (CNC) are polydisperse rod-shaped particles of crystalline cellulose I, typically prepared by sulfuric acid hydrolysis of natural cellulose fibres to give aqueous colloidal suspensions stabilized by sulfate half-ester groups. Sufficiently dilute suspensions are isotropic fluids, but as the concentration of CNC in water is increased, a critical concentration is reached where a spontaneously ordered phase is observed. The (equilibrium) phase separation of the ordered chiral nematic phase is in competition with a tendency of the CNC suspension to form a gel. Qualitatively, factors that reduce the stability of the CNC suspension favour the onset of gelation. The chiral nematic structure is preserved, at least partially, when the suspension dries. Solid chiral nematic films of cellulose are of interest for their optical and templating properties, but the preparation of the films requires improvement. The processes that govern the formation of solid chiral nematic films from CNC suspensions include phase separation, gelation and also the effects of shear on CNC orientation during evaporation. Some insight into these processes is provided by polarized light microscopy, which indicates that the relaxation of shear-induced orientation to give a chiral nematic structure may occur via an intermediate twist-bend state.

Professor Derek Gray, McGill University, Canada

Professor Derek Gray, McGill University, CanadaBorn in Belfast, Northern Ireland, Dr Gray is currently Professor Emeritus in the Department of Chemistry, McGill University, Montreal, Canada. His research interests are in polymer, colloid and surface chemistry, with emphasis on the properties of wood, pulp and paper. Discoveries from his research group have included the first reported formation of liquid crystalline cellulose derivatives, and the preparation and self assembly of cellulose nanocrystals to give chiral nematic suspensions and ordered films. These unexpected properties have led to wide interest in the production and application of nanocellulosic materials. He received Anselme Payen award of the American Chemical Society in 1994, and the Marcus Wallenberg Prize in 2013 for scientific achievements relevant to forestry and forest industries. |

|

| 11:45 - 12:30 |

Cellulose Nanocrystals in Pickering Emulsions and Polymer Systems

Cellulose nanocrystals (CNCs), obtained by strong sulphuric acid hydrolysis of cellulosic biomass, are surface-charged, nano-scaled particles capable of self-assembly. CNCs possess unique optical and electromagnetic properties originating from their ability to form chiral nematic organisation under the influence of the Earth’s magnet. Dr Hamad’s presentation will focus on the application of CNCs to stabilise Pickering emulsions, as well as functionalising CNC surfaces to render them suitable for applications in polymer nanocomposites and flexible electronics. The effects of CNC concentration and type of oil phase on the properties of medium- and high-internal phase Pickering emulsions have been studies, and details of the stabilisation mechanism will be discussed. The maximum oil phase volume that can be stabilised by CNCs is 87% when the CNC concentration is 0.6 wt. % and slightly decreases to 83% when CNC concentration is increased to 1.2 wt. % or higher. Dr Hamad will also present in situ polymerisation strategies, in the presence of CNCs, for controlling the crystallinity and plasticity in thermoplastic polymer, as well as methods for tailoring cross-linking density and toughness in thermoset resins. He will further explore use of CNCs, along with conjugated polymers, to develop flexible, organic, semiconducting materials.

Dr Wadood Y. Hamad, FPInnovations and University of British Columbia, Canada

Dr Wadood Y. Hamad, FPInnovations and University of British Columbia, CanadaWadood Y. Hamad, M.A, Ph.D., Principal Scientist & Research Leader in cellulosic nanomaterials at FPInnovations, Vancouver, Canada and Adjunct Professor at the Department of Chemistry, University of British Columbia, specialises in nanotechnology and polymer physics. Dr Hamad leads a group of 10 scientists and technologists, and several graduate students and post-doctoral fellows. Over the past 12 years, he has led major activities in the extraction, scale-up and commercialisation of cellulose nanocrystals (CNC), as well as the development of product platform technologies using CNCs in polymer nanocomposites, emulsions, photonics, flexible electronics and optoelectronics. He is the inventor/co-inventor of 22 patents and the author of over 100 peer-reviewed papers, several single-author chapters and 3 monographs, more recently Cellulose Nanocrystals: Properties, Production and Applications (Wiley 2017). |

Chair

Professor Steve Eichhorn, College of Engineering, Maths & Physical Sciences, University of Exeter, UK

Professor Steve Eichhorn, College of Engineering, Maths & Physical Sciences, University of Exeter, UK

Professor Steve Eichhorn is Chair in Materials Science within the College of Engineering, Maths & Physical Sciences. Steve joined Exeter in 2011, prior to which he was at the University of Manchester for 16 years, both as a PhD student and a member of academic staff in the School of Materials. He originally trained as a physicist, at Leeds (Physics, 1990-1993), but works closely with engineers, biologists, physicists and chemists. His research focuses on the mechanical properties and interfaces in natural and sustainable materials, particularly cellulose fibres and composites. He has made notable contributions to the field of cellulosic nanomaterials, and was awarded the 2012 Rosenhain Medal and award. He is currently the chair of the American Chemical Society’s Cellulose and Renewable Materials Division.

| 13:30 - 14:15 |

Cellulose Nanomaterials as Green Nanoreinforcements for Polymer Nanocomposites

Unexpected and attractive properties can be observed when decreasing the size of a material down to the nanoscale. Cellulose is no exception to the rule. In addition, the highly reactive surface of cellulose resulting from the high density of hydroxyl groups is exacerbated at this scale. Different forms of cellulose nanomaterials, resulting from a top-down deconstructing strategy (cellulose nanocrystals, cellulose nanofibrils) or bottom-up strategy (bacterial cellulose) are potentially useful for a large number of industrial applications. These include the paper and cardboard industry, use as reinforcing filler in polymer nanocomposites, basis for low-density foams, additive in adhesives and paints, as well as a wide variety of filtration, electronic, food, hygiene, cosmetic, and medical products. However, it is as a biobased reinforcing nanofiller that they have attracted significant interest during the last 20 years. Impressive mechanical properties can be obtained for these materials. They obviously depend on the type of nanomaterial used, but the crucial point is the processing technique. As for any nanoparticle, the main issue is related to their homogeneous dispersion within the polymeric matrix. An important challenge consists in the preparation of polymer nanocomposites using industrial melt processing techniques, avoiding the liquid medium methods.

Professor Alain Dufresne, INP Pagora, Grenoble Institute of Technology, France

Professor Alain Dufresne, INP Pagora, Grenoble Institute of Technology, FranceAlain Dufresne received his PhD in 1991 from the Department of Electronics at the National Institute of Applied Science in Toulouse (France). He was then Postdoctoral Research Associate at Polytechnique Montreal (Canada), and Temporary Lecturer and Research Assistant at the National Institute of Applied Science in Lyon (France). He was appointed Associate Professor in 1993, and then Professor in 2001, at Joseph Fourier University in Grenoble (France). He is now, and since 2003, Professor at Grenoble Institute of Technology. He has been visiting Professor at the Federal University of Rio de Janeiro (Brazil), at National University of Malaysia (Malaysia), and at the Brazilian Agricultural Research Corporation (Embrapa) in Fortaleza (Brazil). His main research interests concern the processing and characterization of polymer nanocomposites reinforced with nanoparticles extracted from renewable resources. He has published over 230 peer-reviewed papers related to these topics. |

|

|---|---|---|

| 14:15 - 15:00 |

Optimizing Cellulose Nanocrystal Surface Chemistry to Enhance Colloidal and Thermal Stability

Cellulose nanocrystals (CNCs) are rod shaped nanoparticles extracted from natural cellulose sources through a hydrolysis procedure which most commonly uses sulfuric acid. Recently, other acids have been used in the hydrolysis procedure to modify CNC properties. CNCs hydrolysed with phosphoric acid have been shown to have increased thermal stability; however, this new procedure has not been optimized. Phosphoric acid-hydrolyzed CNCs (P-CNCs) have low surface charge, causing them to aggregate in suspension and even more so after heat treatment. A design of experiments approach was completed to study the effects of hydrolysis parameters on P-CNC size, aspect ratio, crystallinity, thermal stability and colloidal stability. Additionally, hydrolyses were performed with both sulfuric and phosphoric acid to yield CNCs with a combination of charged surface groups. It was found that the hydrolysis conditions have significant effects on several CNC properties, most notably on colloidal stability and aspect ratio. This study proposes facile methods (and small tweaks to industrial production protocols) for controlling key properties which are crucial for high temperature/pressure applications of CNCs, such as oil and gas drilling and completion fluids. Anticipated Paper Title: Design of Experiments Optimization of Cellulose Nanocrystals Produced through Phosphoric Acid Hydrolysis for Enhanced Colloidal and Thermal Stability

Professor Emily Cranston, Department of Chemical Engineering, McMaster University, Canada

Professor Emily Cranston, Department of Chemical Engineering, McMaster University, CanadaEmily Cranston is an Associate Professor in Chemical Engineering at McMaster University in Canada. Her research focuses on sustainable nanocomposites and hybrid materials from cellulose and other biopolymers. Her academic path began at McGill University where she received her Honours B.Sc. in Chemistry with bio-organic specialty and a PhD in Materials Chemistry in the group of Professor Derek Gray. The study of value-added products from cellulose took her to Stockholm, Sweden as a postdoctoral researcher at the Royal Institute of Technology (KTH) before she returned to Canada in 2011. Emily is the recipient of the KINGFA Young Investigator’s Award from the American Chemical Society’s Cellulose & Renewable Materials division and is a Distinguished Engineering Fellow at McMaster University. |

|

| 15:00 - 15:30 | Tea break | |

| 15:30 - 16:15 |

Watching Paper Dry: Making Photonic Structures form Cellulose Nanocrystals

Cellulose nanocrystals (CNCs) obtained from paper or cotton are of great interest for many applications. In water, CNCs spontaneously form a chiral nematic lyotropic liquid crystalline phase, which can be preserved in dried films. The helicoidal structural organization of the CNCs in these films resembles the Bouligand structure of chitin found in crabs and other arthropods, and leads the films to be iridescent.

Professor Mark MacLachlan, Department of Chemistry, University of British Columbia, Canada

Professor Mark MacLachlan, Department of Chemistry, University of British Columbia, CanadaMark MacLachlan received his B.Sc. degree in chemistry at UBC and Ph.D. degree from the University of Toronto (1999). After an NSERC Postdoctoral Fellowship at M.I.T., he returned to UBC to begin his independent career. Mark’s research interests span supramolecular chemistry, macrocycle chemistry, nanomaterials, mesoporous materials, photonic structures, and biopolymers. He has received an E. W. R. Steacie Memorial Fellowship (2012-2014), the Strem Award for Pure or Applied Inorganic Chemistry from the Canadian Society for Chemistry (CSC) (2013), the Rutherford Medal of the Royal Society of Canada (RSC) (2013), the Steacie Prize (2014), and the Award for Excellence in Materials Chemistry of the CSC (2015). He is a Fellow of the Royal Society of Canada and holds the Canada Research Chair in Supramolecular Materials. |

|

| 16:15 - 17:00 |

Better together: Synergy in Nanocellulose Blends

Cellulose nanopapers have gained significant attention in the recent years as large-scale reinforcement for high-loading cellulose composites, substrates for printed electronics and filter nanopapers for water treatment applications. The mechanical properties of nanopapers are of fundamental importance for all these applications. Cellulose nanopapers can simply be prepared by filtration of nanocellulose. It was already demonstrated that the mechanical properties of cellulose nanopapers can be tailored by the fineness of the fibrils used or by modifying nanocellulose fibrils for instance by polymer adsorption but nanocellulose blends remain underexplored. We show that the mechanical and physical properties of nanopapers can be tuned by creating hierarchical structures in nanopapers by blending various grades of nanocellulose, i.e. bacterial cellulose, cellulose nanofibrils extracted from bagasse by mechanical and chemical pre-treatments. We found that nanopapers made from blends of two or even more nanocellulose grades show synergistic effects resulting in improved stiffness, strength, ductility and toughness and physical properties.

Professor Alexander Bismarck, University of Vienna and Department of Chemical Engineering, Imperial College London, UK

Professor Alexander Bismarck, University of Vienna and Department of Chemical Engineering, Imperial College London, UKAlexander Bismarck is Professor of Materials Chemistry and Head of the Institute of Materials Chemistry in the Faculty of Chemistry of the University of Vienna, which he joined in 2012, and Polymer Materials in the Department of Chemical Engineering at Imperial College London. His research group, the Polymer and Composite Engineering (PaCE) Group is split between the two sites. Prior his first academic appointment he held a permanent position as R&D engineer at Sulzer Innotec/Sulzer Composites (later Gurit Suprem) Winterthur, Switzerland. PaCE research activities are organised into four major themes: advanced and multifunctional composites, green materials, water-soluble polymers and macroporous polymers. Their research focus is on the development, engineering and processing of hierarchical, i.e. fibre reinforced nano-composites as well as multifunctional composites. |

Chair

Dr Silvia Vignolini, Department of Chemistry, University of Cambridge, UK

Dr Silvia Vignolini, Department of Chemistry, University of Cambridge, UK

Dr Silvia Vignolini graduated with Laude in Physics at the University of Florence, Italy. In 2009, she was awarded a PhD in Condensed Matter Physics at the European Laboratory for non-Linear Spectroscopy and the Physics Department at the University of Florence. In 2010, she joined the Soft NanoPhotonics group at the Cavendish Laboratory at in Cambridge, UK as a group as a research associate. In 2013, she was awarded a BBSRC David Philip Fellowship. She joined the Chemistry Department in Cambridge as a Lecturer in 2014, and in 2015 she was awarded an ERC Starting Grant.

| 09:00 - 09:45 |

Folding of Xylan onto Cellulose Fibrils in Plant Cell Walls Revealed by Solid-state NMR

Exploitation of plant lignocellulosic biomass is hampered by our ignorance of the molecular basis for its properties such as strength and digestibility. Xylan, the most prevalent non-cellulosic polysaccharide, binds to cellulose microfibrils. The nature of this interaction remains unclear, despite its importance. Here it is shown that the majority of xylan, which forms a 3-fold helical screw in solution, flattens into a 2-fold helical screw ribbon to bind intimately to cellulose microfibrils in the cell wall. 13C solid-state magic angle spinning NMR spectroscopy, supported by in silico predictions of chemical shifts, shows both 2- and 3-fold screw xylan conformations are present in fresh Arabidopsis stems. The 2-fold screw xylan is spatially close to cellulose, and has similar rigidity to the cellulose microfibrils, but reverts to the 3-fold screw conformation in the cellulose-deficient irx3 mutant. The discovery that induced polysaccharide conformation underlies cell wall assembly provides new principles to understand biomass properties. The cell wall structure suggests strategies for improved extraction of nanocellulose from wood.

Professor Paul Dupree, Department of Biochemistry, University of Cambridge, UK

Professor Paul Dupree, Department of Biochemistry, University of Cambridge, UKProfessor Paul Dupree is a Professor of Biochemistry at the University of Cambridge. He has studied the biosynthesis and structure of plant cell walls since 1996. He has made contributions to understanding xylan and cellulose biosynthesis (2010, PNAS, 107:17409; 2012, PNAS, 109:989; 2016 Nature Comm. 7:11656) and enzymes for degradation (2015 Nature Comm., 6:7481). He studies the activity of lytic polysaccharide monoxoygenases (LPMOs) in polysaccharide degradation, recently revealing the degradation stimulating activity of a new family of LPMOs AA13 (2015, Nature Comm., 6:596) and the substrate specificity and products of cellulose active LPMOs (2011, PNAS, 108, 15079; 2016 Nature Chem. Biol 12:298). Recent work has revealed aspects of the molecular architecture of cellulose:xylan polysaccharide interactions in plant cell walls using solid state NMR (Dupree et al. 2015, Simmons et al. 2016). He directed the BBSRC Sustainable Bioenergy Centre Cell Wall Sugars Programme from 2009-2014. He was designated by ThomsonReuters as one of the world’s most highly cited scientists (2015 highlycited.com). |

|

|---|---|---|

| 09:45 - 10:30 |

Structure of Native Cellulose Microfibrils, the Starting Point for Nanocellulose Production

There is an emerging consensus that higher plants synthesise cellulose microfibrils that initially comprise 18 chains. However the mean number of chains per microfibril in situ is usually greater than 18, sometimes much greater. Microfibrils from woody tissues of conifers, grasses and dicotyledonous plants, and from organs like cotton hairs, all differ in detailed structure and mean diameter. Diameters increase further when aggregated microfibrils are isolated. Because surface chains differ, the tensile properties of the cellulose may be augmented by increasing microfibril diameter. Association of microfibrils with anionic polysaccharides in primary cell walls and mucilages leads to in vivo mechanisms of disaggregation that may be relevant to the preparation of nanofibrillar cellulose products. For the preparation of nanocrystalline celluloses, the key issue is the nature and axial spacing of disordered domains at which axial scission can be initiated. These disordered domains do not, as has often been suggested, take the form of large blocks occupying much of the length of the microfibril. They are more likely to be located at chain ends or at places where the microfibril has been mechanically damaged, but their structure and the reasons for their sensitivity to acid hydrolysis need better characterisation.

Dr Michael C Jarvis, School of Chemistry, Glasgow University and IBioIC, Strathclyde University, Glasgow

Dr Michael C Jarvis, School of Chemistry, Glasgow University and IBioIC, Strathclyde University, GlasgowMike Jarvis was educated in Glasgow and taught at Glasgow University for nearly 40 years, first in agricultural chemistry and latterly in environmental chemistry. His research group worked on plant cell walls and their constituent polymers: initially on the cell walls of crop plants, in collaboration with plant breeders and the food industry, but latterly trees and timber. He has applied a wide range of techniques to the structure of cellulose and the structural basis for the strength of cellulosic materials. He has also been closely concerned in technology development within the timber industry. He retired in 2015 but continues to work as a consultant for IBioIC, the Scottish Innovation Centre in Industrial Biotechnology. |

|

| 10:30 - 11:00 | Coffee break | |

| 11:00 - 11:45 |

Residual Wood Polymers Facilitate Compounding of Microfibrillated Cellulose with Non-polar Media

Microfibrillated cellulose is a fascinating material with an obvious potential for composite reinforcement due to its excellent mechanics together with high specific surface area. However, in order to utilise this potential, commercially viable solutions to important technological challenges have to be found. Notably, the distinct hydrophilicity of microfibrillated cellulose prevents efficient drying without loss in specific surface area, necessitating storage and processing in wet condition. This greatly hinders compounding with important technical polymers immiscible with water. Differently from cellulose, the chemistry of the major wood polymers lignin and hemicellulose is much more diverse in terms of functional groups. Specifically, the aromatic moieties present in lignin and acetyl groups in hemicellulose provide distinctly less polar surface-chemical functionality compared to hydroxyl groups, which dominate the surface chemical character of cellulose. Experimental evidence demonstrates that the surface-chemical functionalities of lignin and hemicellulose can be utilised to the benefit dispersion of microfibrillated cellulose in non-polar media and promote interfacial adhesion between fibrils and polymer matrices. It should be noted that lignin and hemicellulose do not provide hydrophobicity to a comparable extent as achievable by chemical modification of cellulose, but may be a cost-efficient alternative to modification in a number of specific cases.

Professor Wolfgang Gindl-Altmutter, Institute of Wood Technology and Renewable Materials, BOKU-Vienna, Austria

Professor Wolfgang Gindl-Altmutter, Institute of Wood Technology and Renewable Materials, BOKU-Vienna, AustriaWolfgang Gindl-Altmutter holds a degree in wood science and is professor for Natural Fibre Materials at BOKU – University of Natural Materials and Life Science, Vienna. He is also the scientific director of Wood K plus, an Austrian non-academic research institute with currently 110 employees, focussing on bridging the gap between academic research and industrial R&D in the forest-based industry. He teaches various lectures in the fields of wood physics and natural fibre materials. His research interests comprise the fundamental understanding of structure-property relationships in cellulosic materials, elucidation of the interface between polymers and lignocellulosic surfaces, and the development of novel materials from lignocellulose value streams in the wood- and pulp&paper industries. |

|

| 11:45 - 12:30 |

Molecular Interactions at Play in Nanocellulose Assembly

Cellulose is often described as strong, stiff and difficult to process, in contrast to commodity plastics. Hydrogen bonding and hydrophobic interactions are often mentioned in the literature as the origin of these particular behaviors, but the description remains qualitative. How can we quantify in a simple way the contribution of different types of molecular interactions in the context of material properties and processing? The crystal structure analysis, molecular modeling including quantum mechanical approaches, thermodynamics data of analogue molecules give clues to the dissection of the different types of energy contribution. Hydroxyl groups of cellulose form hydrogen bond comparable to other simple alcohols. Trends of heat of vaporization of alkyl-alcohols and alkanes suggests a stabilization by such hydroxyl-group hydrogen bonding to be of the order of 24 kJ/mol, while London dispersion force contributes to about 0.41 kJ/mol/dalton. Simple arithmetic gives striking agreement with experimental enthalpy of sublimation of small sugars, where the major cohesive energy comes from hydrogen bonds. For cellulose, due to the reduced number of hydroxyl groups, London dispersion force would be the major component in intermolecular cohesion. The role of multipolar interactions and hydrophobic interactions will be also discussed.

Dr Yoshiharu Nishiyama, CERMAV-CNRS, France

Dr Yoshiharu Nishiyama, CERMAV-CNRS, FranceDr Yoshiharu Nishiyama is a researcher at the Centre de Recherches sur les Macromolécules Végétales (CERMAV) – CNRS. He obtained his PhD at the University of Tokyo in 2000. He was assistant professor at the graduate school of Agricultural and Life Science at the university of Tokyo (2000-2004) before joining CERMAV. His research covers the structure determination by high-resolution fibre diffraction studies on cellulose and its analogues, molecular modelling of polysaccharides, heterogeneous modifications of nanocellulose and higher order structures in wood cell wall. He is recipient of Japan Wood Research Society Prize (2008), Hayashi Jisuke Award (2012) and Marcus Wallenberg Prize (2015). |

Chair

Dr Sameer S. Rahatekar, School of Aerospace, Transport and Manufacturing Engineering, Cranfield University, UK

Dr Sameer S. Rahatekar, School of Aerospace, Transport and Manufacturing Engineering, Cranfield University, UK

Dr Sameer Rahatekar is Research Lecturer in Manufacturing at School of Aerospace, Transport and Manufacturing at Cranfield University. He earned his PhD at University of Cambridge where he worked on nano-composites modelling and manufacturing. He worked as a postdoctoral researcher at National Institute of Standards and Technology (NIST), USA where he worked on manufacturing strong and multi-functional cellulose fibres using ionic liquids as a benign solvent. He was a lecturer at the Advanced Composite Centre for Innovation and Science (ACCIS), Aerospace Engineering at University of Bristol where he worked on manufacturing strong of cellulose fibres as precursors for carbon fibres and on nano-particles reinforced carbon/glass fibre composites for improved fracture toughness and lightning strike protection used in aerospace industry. He played a key role is winning Engineering and Physical Science Research Council Grant “Manufacturing High Performance Cellulose Fibres to Replace Glass fibres & Carbon Fibre Precursors”; he is acting as a co-investigator and project manager for this project.

| 13:30 - 14:15 |

Understanding the Structure of the Plant Cellulose Synthase Complex and its Relationship to Cellulose Microfibril Structure

In higher plants, cellulose is synthesised at the plasma membrane by a very large membrane-bound protein complex. This complex is driven through the plane of the plasma membrane while catalysing the formation of 18 to 24 individual cellulose chains that bind together to form a cellulose microfibril. The cellulose synthase complex requires three different, but related, types of catalytic subunits. The organisation of these catalytic subunits, known as CESA proteins within the cellulose synthase complex is critical for the formation of the cellulose microfibril produced. Analysis suggests that some of catalytic subunits are more important for the assembly of complex while others are more critical for producing a cellulose microfibril. While much of the focus has been on cellulose synthesis in higher plants, a wide variety of different types of cellulose synthase complexes exist within the plant kingdom. The availability of extensive genome sequence information suggests that it may now be timely to consider engineering plants to make different kinds of cellulose and to determine what effect this may have on the properties and utility of the cellulose produced.

Professor Simon Turner, School of Biological Science, University of Manchester, UK

Professor Simon Turner, School of Biological Science, University of Manchester, UKSimon Turner currently holds the George Harrison Professor of Botany at the University of Manchester. He has held this position since 2004 having joined the University as a lecturer in 1995 following his work as a postdoctoral worker in the lab of Professor Chris Somerville at the Carnegie Institute at Stanford University. During this period he identified the first irx mutants that allowed him to identify the genes required for cellulose synthesis in the secondary cell wall that started his research into cellulose synthesis. Cellulose synthesis continues to be one of his main interests particularly the relationship between the enzyme that synthesises cellulose and the microfibrils it produces. Other research interests include the regulation of plant vascular development and how it can be manipulated to increase plant growth. |

|

|---|---|---|

| 14:15 - 15:00 |

Wood nanotechnology based on porous nanocellulosic templates

Wood modification is a large technical area including salt impregnation, coating and adhesive technologies as well polymer-impregnated wood. Inspired by recent progress in the area of nano-cellulose materials, we are extending these approaches to build a wood nanotechnology platform. In wood cell wall bulking methodologies, polymers with affinity to wood become located inside the cell wall. New methodologies make it possible to bring in other polymers, inorganic nanoparticles and carry out chemical functionalization in the cell wall (Burgert et al 2015). The property range for modified wood can then be extended through tailoring of the cell wall structure at molecular and nanoscale levels. Methods for increasing the pore space in the wood cell wall are discussed, and related to results in terms of morphology and specific surface area. Examples are provided, where the pore space is modified by the use of inorganic nanoparticles diffusing into the pores. This alters thermal degradation behavior, and improves fire retardancy. Additional modification approaches are discussed, including methods to prepare optically functional materials. Functions include combinations of load-bearing properties, diffused luminescence and lasing properties of wood. The implications for other functionalities will be discussed as well as the potential for large scale applications.

Professor Lars Berglund, KTH Royal Institute of Technology, Sweden

Professor Lars Berglund, KTH Royal Institute of Technology, SwedenLars Berglund is Professor of Wood and Wood Composites at KTH Royal Institute of Technology in Stockholm. He has been a visiting researcher at Stanford University, Cornell University and Kyoto University. His research interest is in nanostructured composite materials; primarily those based on cellulose. An important challenge is transparent cellulosic nanomaterials, which also can serve as load-bearing engineering materials. Professor Berglund has published more than 300 journal papers, obtained around 10 patents, examined more than 20 PhDs and is a member of the Royal Swedish Academy of Engineering Sciences. He holds an ERC Advanced Grant on Nanotechnologies for Transparent Wood. He is a 'highly cited' author on Web of Science, has more than 21,000 citations and an H-index of 70. |

|

| 15:00 - 15:30 | Tea break | |

| 15:30 - 16:15 |

Bioinspired Self-assembled CNC Blends for Superior Mechanical Properties

We report the fabrication of pristine, tough cholesteric cellulose nanocrystals (CNC) films with varying ratios of short (w-CNC) and long aspect ratio (t-CNC) CNCs using evaporation induced self-assembly (EISA). The effect of the addition of the long aspect ratio t-CNCs on the structure of the w-CNCs is studied using SEM, TEM imaging, UV-Vis-NIR chiral dichroism (CD) and reflectance spectra. We find that the helical pitch of the cholesteric films can be controlled in a non-linear fashion, between 700 and 220 nm, by tuning the t-CNC content. In agreement literature results, the neat w CNC films were found to be brittle, inflexible and difficult to handle. However, the addition of even a small percentage (1%) of t-CNCs was found to cause significant improvement in the films properties. The in-plane mechanical properties of these films were found to improve non-linearly with t-CNC content, with the modulus, tensile strength and strain to failure nearly doubling with 10 % of t-CNCs. Overall toughness enhancement of 8 times were seen. These films reflect some of the highest properties reported for pristine CNC-Bouligand films. We propose that these films as excellent starting materials for Bouligand nanocomposite fabrication through template filling, or one-step EISA processing.

Dr Jeffrey W. Gilman, National Institute of Standards and Technology (NIST), USA

Dr Jeffrey W. Gilman, National Institute of Standards and Technology (NIST), USADr Jeffrey W. Gilman received his B. A. in chemistry from Ithaca College, and his Ph.D. in organic chemistry from the University of California, Irvine from Kenneth Shea where he developed methods for the synthesis of the anticancer drug, Taxol. He was a post doctoral student of Raj Razdan at HG Pars Pharmaceuticals, with whom he worked on THC. He developed preceramic polymers such as polyoligosilsesquioxane, POSS, nanomaterials at the Air Force Research Lab, and after a year at Enthone-OMI developing waterborne photo-imageable solder mask coatings he joined NIST as a research polymer chemist. Dr Gilman’s work at NIST has resulted in new approaches to flame retarding polymers using nano-materials. He is currently the leader of the Composites Project at NIST. His recent work focuses on cellulose nano materials and measurements using Forster resonance energy transfer (FRET) and fluorescence life-time imaging (FLIM), to characterize interfaces in composites. |

|

| 16:15 - 17:00 | Panel discussion: future directions |